Mine Dewatering

22 May 2014Dewatering and groundwater control is an important part of many open pit and underground mines. When mining below the water table groundwater is an inevitable challenge. On some projects groundwater will be a minor impediment that can be dealt with on an ad-hoc basis. On other projects, and in other geological settings, planning and execution of dewatering may be fundamental to the viability of the mine and may require very large resources and management.

Unfortunately, in the past mining projects have suffered setbacks (such as large slope failures) or even had to be abandoned (e.g. due to flooding) as result of poorly managed groundwater and dewatering issues. However, this need not be the case; with careful design and planning groundwater can be controlled, by various means, to provide safe mining conditions and a good return on the money spent.

This blog discusses good practice in mine dewatering.

OBJECTIVES OF MINE DEWATERING

It is essential that the objectives of mine dewatering are understood from the early stages (feasibility study or earlier) of a mining project. The objectives of mine dewatering are not always as simple as ‘keeping the mine dry’.

There are two objectives of mine dewatering. A given mine site may need to focus on one or both of these objectives:

- General mine dewatering (control of inflows and lowering of groundwater levels). This is the classic dewatering activity which involves intercepting or collecting groundwater and surface water inflows and pumping the water away to create workably dry conditions in the relevant areas or levels of the mine. This can involve pumping very large quantities of water. Mine dewatering can also involve measures to keep water out (groundwater exclusion methods, such as slurry walls or grout curtains) which can reduce inflows.

- Pore water pressure reduction (depressurization around open pit slopes, pit bottoms and shafts and roadways). This is a more subtle objective which recognizes that high pore water pressures can have a significant destabilizing effect on slopes and underground openings, not only in unconsolidated deposits and soft rocks, but also in fractured hard rocks. Depressurization systems are used to lower pore water pressures, which increase effective stresses and increase the shear strength of the rock. This has benefits for geotechnical design, for example by allowing steeper open pit slopes without a reduction in factor of safety. In many cases the water flow rate from depressurization systems will be relatively low, but they can have a dramatic effect on geotechnical properties and pit slope stability.

BENEFITS OF MINE DEWATERING

Where a planned programme of mine dewatering is deployed, the mine will typically see several benefits, including:

- General improvement in working conditions and efficiency: better trafficking and diggability, reduced downtime due to pit flooding.

- Improved slope stability and safety: lowering of groundwater levels and reduction in pore water pressures can allow steeper open pit slope angles to be used, while maintaining or increasing factors of safety.

- Reduced blasting costs: lowering groundwater levels in advance of working will provide dry blast holes, reducing the need for more costly emulsion explosives.

- Reduction in haulage costs: Dry ore and waste rock weigh less than wet material, so dewatering of rock provides a haulage cost saving.

Mine dewatering costs money, and the major capital spend for dewatering is often early in the project during pre-production or production ramp up. It is essential that the objectives and potential benefits for the mine in question are clearly identified at an early stage. This will make sure that the most cost effective dewatering scheme can be developed, and can also be phased to match the mine plan. There may be opportunities to delay installation of some elements of the dewatering to improve cash flow, but equally it can be a false economy to delay dewatering works until the last minute, in case unexpected geological conditions create delays or reveal new hydrogeological challenges.

Successful planning of mine dewatering requires a hydrogeological assessment of the site and its surroundings. This may be achieved through desk study, borehole investigations, pumping tests and numerical groundwater modelling. It is also essential that the most appropriate dewatering techniques are selected and used, because the choice of technique can have a huge influence on the effectiveness of the dewatering.

POSSIBLE APPROACHES TO MINE DEWATERING

Mine dewatering can be achieved using a range of techniques, depending on the geology and the type of mine. The choice of technique may also be influenced by the capability of local drillers and contractors or the availability of equipment.

Groundwater Control by Pumping

Potential techniques include:

- In-pit pumping – used to pump from sump areas or wells located within the mine.

- Perimeter dewatering wells – used to intercept lateral groundwater flow into the pit and to lower groundwater levels in advance of mining.

Groundwater Control by Exclusion

Potential techniques include:

- Cut-off walls – slurry walls used to exclude groundwater from shallow alluvial or drift deposits, or to seal off preferential flow along permeable strata.

- Grouting and artificial ground freezing – used to seal off preferential groundwater pathways, or to reduce ground permeability in advance of shaft sinking or roadway development.

Groundwater Control for Depressurization

Potential techniques include:

- Depressurization drains – inclined or horizontal drains used to provide permeable pathways to allow trapped or slowly draining groundwater behind pit slopes to bleed off into the pit.

- Vertical drains – vertical boreholes drilled and filled with permeable material (sand or gravel) to provide a permeable downward pathway through low permeability layers or other geological features which would otherwise prevent vertical groundwater flow. These vertical drains can be used to help perched water in shallow strata drain downward into deeper strata that have been depressurized by pumping.

- Relief wells – vertical boreholes drilled and filled with permeable material (sand or gravel) to provide a permeable upward pathway to relieve high pore water pressures beneath the base of a pit or below a mine level to reduce the risk of hydraulic uplift or heave.

- Drainage adits or galleries – constructed to act as large scale drainage features behind pit slopes for open pit mines.

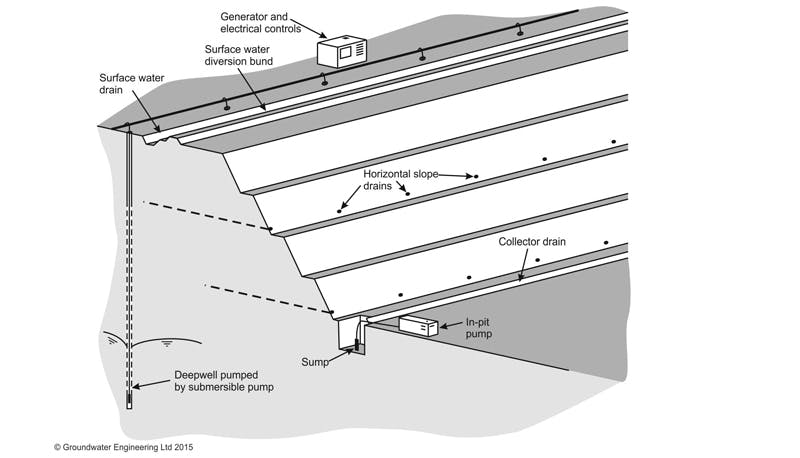

Surface Water Control

Surface water must also be controlled to allow efficient mining operations. Runoff (including spring snow thaw in cold regions) from the surrounding land surface must be diverted away from the mine, for example by using collector drains and diversion bunds. Within a mine any surface water must be controlled by the drains and sumps to collect the water away from working areas. In areas affected by tropical storms and monsoons the surface water pumping system may have to have a very large pumping capacity and sump storage volume to deal with storm events.

MINE DEWATERING TECHNIQUES BASED ON PUMPING

In-pit pumping

This is the simplest form of mine dewatering by pumping, with potentially the lowest capital costs. This technique allows groundwater to enter the mine (open pit or underground mine), where it is directed (via drains and ditches) to sumps, from where it is pumped away to the surface. The drawback with this approach is that water levels cannot easily be lowered in advance of mining; hence there will always be water and wet areas within the lower sections of the mine, which can constrain the choices of mining methods and reduce operational efficiency. Furthermore, in-pit pumping will tend to produce ‘dirty water’, with significant suspended solids content, which may require treatment to remove sediment prior to discharge.

In-pit pumping is normally carried out by robust pumps capable of pumping dirty water. Pump sets may be of the electric submersible type or of the self-priming surface pump type. Mine dewatering pump sets typically have capacities in the range 20 to 200 l/s (72 to 720 m3/h), with maximum delivery heads of 150 m. Higher flow rates can be achieved with multiple units in parallel. For deeper open pits, higher discharge heads are achieved by arranging pumps in series, with booster pumps located partway up the pit slopes.

Deep wells pumped by submersible pumps

This method involves drilling deep wells (most commonly using rotary drilling rigs, by either reverse circulation or direct circulation methods, depending on diameter), into which suitable perforated and unperforated well liner is installed, surrounded by any necessary filter media. The wells are then typically pumped by electrically-driven slimline borehole submersible pumps. There are two main advantages to this technique. Firstly, appropriately designed and constructed wells which have been suitably developed will normally produce ‘clean water’ with very little suspended solids, thereby reducing water treatment requirements. Secondly, an array of wells can be used as a ‘pre-drainage’ system to lower groundwater levels in advance of mining, and to maintain groundwater levels below the base of an open pit, or below upper levels in an underground mine. This can allow mining to be carried out in very dry conditions, with corresponding improvements in efficiency for blasting, excavation and haulage. The downside of the use of deep wells is the relatively high capital cost associated with well installation.

Deep wells can be installed to depths in excess of 500 m, with finished internal diameters typically in the range 150 to 450mm. Borehole pump capacities range from 1 l/s (3.6 m3/h) to 100 l/s (360 m3/h).

Slope depressurization drains

In some hydrogeological settings, dewatering of the mine to provide dry mining conditions is not sufficient to ensure adequate geotechnical stability of the pit slopes and other key areas. There may be geological features such as faults or bedding planes which prevent the slopes from draining even when the main aquifers are depressurized, or it may simply be that the rock is of such low hydraulic conductivity that pore water pressure reductions are very slow. In open pits drainage of pit slopes can be improved by drilling an array of sub-horizontal drains into the slopes to allow water pressures to reduce by bleeding off small quantities of water into the pit. Slope drains are normally drilled at diameters of 50 to 100 mm using specialist horizontal drilling rigs. Drilled lengths to up to 300 m are possible. In underground mines, drain holes may be drilled outward from roadways and access declines to aid depressurization of the rock to improve stability. It may be possible to connect flowing drain holes to a separate ‘clean water’ pumping system, to reduce the volumes of ‘dirty water’ requiring treatment that are generated by the mine.

Specialist drainage methods

Less commonly, more specialist dewatering methods are used in open pit mines. The can include lines of wellpoints or eductor wells used to stabilize fine grained granular deposits (silts or sands) where they are exposed in the pit slopes, or drainage tunnels and adits driven near the open pit to promote drainage in fissured rocks of low hydraulic conductivity.

MANAGEMENT OF WATER DISCHARGES

A key aspect of mine dewatering systems is that they will generate water from pumped wells or sumps, from flowing drains, and from surface water collection systems. Some of this water will be ‘dirty water’ and will require some form of treatment (most commonly to remove suspended solids) before it can be used or disposed of. Some of the water may be ‘clean water’ requiring little or no treatment. As a general rule, it is good practice to maximize the proportion of clean water and minimize the proportion of dirty water.

Pumped water may be directed to:

- Use on the mine site for mineral processing or tailings management.

- Use on site for dust suppression.

- Disposal by discharge to surface water bodies.

- Disposal by re-injection or re-infiltration into the aquifer by re-injection wells or open infiltration ponds.

- Use on site (following treatment) for drinking water supplies in the mine camp and facilities.

.jpg?auto=compress%2Cformat&cs=strip&ixlib=php-1.1.0&s=48d3f3c647435328228fec2d7eeb9dfc)

On some mine sites the water demand will exceed the dewatering flow rate and the site will not have a net discharge, and may have to import water to top up process use. On other sites the dewatering flow rate will exceed the water required for on-site use and the excess water must be disposed of. If dewatering flow rates and water demands vary seasonally then a mine may have a water balance surplus in one part of the year and a deficit later in the year.

Use and disposal of water from dewatering will be strongly influenced the quality of the pumped water, including pH, salinity and dissolved minerals, and must be compliant with local and national regulations applicable at the mine site.

GROUNDWATER INVESTIGATIONS

Mine dewatering requires a thorough understanding of the hydrogeology and hydrology of the site. There are several groundwater investigation techniques which can play a key role in the development of mine dewatering systems, including:

Hydrogeological desk studies

Desk top studies and research into existing information such as geological maps, and information from neighbouring mines, can be a very cost effective way to identify groundwater problems at an early stage. Numerical groundwater modelling can be used to assess likely dewatering flow rates, distance of influence and the potential for adverse environmental impacts.

Installation of monitoring wells

Monitoring wells and specialist piezometers installed in advance of dewatering can provide valuable data on hydrogeological conditions, and can be used for permeability testing or groundwater quality sampling.

Pumping tests

Pumping tests are a reliable way of determining representative mass hydraulic conductivity of soils and rocks, and of providing other information on groundwater conditions, including obtaining representative groundwater quality samples for testing. The tests involve pumping a well at a controlled rate, while monitoring flow rate and drawdown of groundwater levels. Pumping tests may involve between a few days to several weeks of continuous pumping. Several wells may be pumped simultaneously to see the cumulative drawdown effect (this is sometimes known as a ‘dewatering trial’).

Borehole permeability tests

A range of tests can be carried out in individual boreholes, including rising and falling head tests, constant head tests, Lugeon tests, Lefranc tests and packer tests. When carried out in accordance with relevant published standards and interpreted appropriately, such tests can provide some indication of hydraulic conductivity values and groundwater conditions.

CONCLUSION

Mining below groundwater level presents many challenges and can result in increased mining costs and reduced efficiency. However, if there is a good programme of hydrogeological characterization and if the dewatering and depressurization methods are carefully selected, safe and efficient mines can be developed to great depth below the water table.

Blog

Dewatering for Basement Construction

12 March 2016Groundwater can be a significant problem when excavating for basement construction. This blog discusses the available techniques that can be used to dewater during basement construction.

Read More