Dewatering for Basement Construction

12 March 2016Many excavations for basement construction will encounter groundwater. This is obviously not ideal – most designers and contractors would prefer a ‘dry’ job to a ‘wet’ one.

If not suitably managed and controlled, groundwater can cause problems for excavation and basement construction. These problems can range from nuisance seepages that reduce the efficiency of construction operations, through to major inflows that can result in instability, inundation and even collapse of the excavation.

While poorly controlled groundwater is an undoubted hazard to construction, this need not be the case. This blog discusses groundwater problems that can occur during basement construction and excavation, and discusses suitable dewatering techniques that can be used to control groundwater.

Adequate control of groundwater is important, and is a necessary part of a well planned basement construction project. In many cases the Planning Authorities, Party Wall Surveyors and other regulatory bodies may want to see evidence that groundwater will be suitably managed during excavation.

Large dewatered excavation in gravel, with sides supported by steel sheet-piles

GROUNDWATER PROBLEMS WHEN CONSTRUCTING BASEMENTS

If an excavation is made without suitable groundwater control various problems can result:

- The excavation may flood as a result of groundwater inflows from water-bearing layers of soil or rocks.

- High pore water pressures in batter slopes at the sides of the excavation may lead to instability or seepage erosion of batter slopes.

- Groundwater uplift pressures beneath the floor of an excavation can give the risk of a base heave or piping failure in the base of the excavation.

- Groundwater pressures can cause excessive hydrostatic loads on excavation retaining structures such as concrete pile walls.

Dewatering methods (also known as groundwater control methods) can be used to control groundwater and avoid these problems.

In addition to groundwater, surface water also needs to be controlled. Any excavation should have a system for surface water control, typically consisting of sump pumps and French drains. Surface water can come from a variety of sources, including rainfall, direct seepage from nearby rivers or lakes, leaking sewers and water mains or even run-off from concrete operations or cleaning of the site excavator! Whatever its source, surface water should be controlled to allow efficient construction operations.

Groundwater control methods are classified into two main types: exclusion or pumping.

GROUNDWATER CONTROL BY EXCLUSION

Groundwater pumping can be reduced or avoided by installing a very low permeability physical cut-off wall to exclude groundwater from the excavation. If a low permeability stratum (such as a clay layer) exists at shallow depth beneath the excavation then the cut-off wall can penetrate down to that stratum to create a full cut-off.

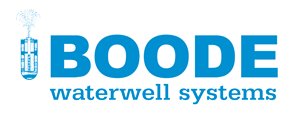

Groundwater control by exclusion

Several different geotechnical methods can be used to form cut-off walls:

- Steel sheet piles

- Concrete secant pile walls

- Concrete diaphragm walls

- Slurry walls and trenches

- Grout curtains (including permeation grouting and jet grouting)

- Freeze walls (produced by artificial ground freezing)

- Compressed air (for tunnels and shafts).

Concrete contiguous pile walls leave a gap between the piles and do not form an effective cut-off to groundwater flow.

Some of the cut-off wall methods are temporary; for example steel sheet-piles can sometimes be extracted at the end of the job. These temporary methods should not have a significant effect on groundwater conditions at the site once the project is completed. However, methods that permanently affect soil permeability (for example grouting) or leave a permanent barrier in place (e.g. concrete secant pile walls) can permanently alter groundwater flow regimes at a site – it is essential that the potential impact of this be assessed at design stage.

Even when a cut-off wall is used some pumping will be required to cope with:

- Groundwater trapped within the cut-off area

- Rainfall and precipitation

- Seepage through the wall and through the ground.

Groundwater control by exclusion is widely used in situations when there is a risk of external impacts (e.g. settlement of nearby structures or detrimental effects on other water users) caused by groundwater lowering. An exclusion system can, if carried out effectively and if ground conditions are favourable, minimise any groundwater lowering outside the dewatered site area.

GROUNDWATER CONTROL BY PUMPING

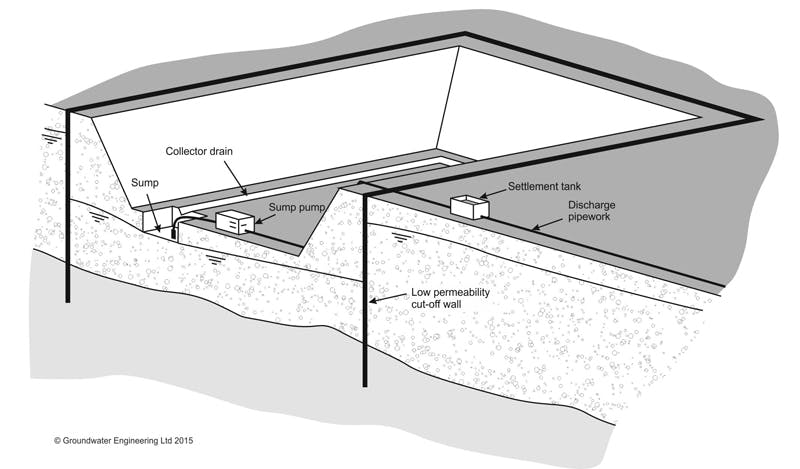

Groundwater control by pumping involves pumping groundwater from an array of wells or sumps with the aim of temporarily lowering groundwater levels to allow excavation to be carried out in dry and stable conditions. Groundwater control by pumping is also known as Groundwater Lowering, Construction Dewatering or simply Dewatering.

Groundwater control by pumping

The most common types of groundwater control by pumping are listed below, in approximate order of sophistication (clicking on the highlighted text well take you a separate blog describing each technique).

On a given site these techniques are not readily interchangeable. Each technique has a relatively narrow range of application relative to two key parameters: the drawdown required and soil permeability.

Wellpoint dewatering in an excavation with concrete contiguous bored pile walls

Before and after wellpoint dewatering – view into a small excavation in sand

POTENTIAL EXTERNAL IMPACTS FROM DEWATERING

When basement dewatering is carried out there is the potential risk of adverse impacts on neighbouring sites – this is one of the reasons that some Planning Authorities require Basement Impact Assessments to be carried out.

There is a wide range of potential impacts from dewatering, which can be categorised in various ways, such as the following groups of impact types:

- Geotechnical impacts – including ground settlements and damage to neighbouring structures.

- Contamination impacts – including drawing in contaminated groundwater from neighbouring sites.

- Water dependent feature impacts – including reducing water flow to any natural springs and wetlands that are in the vicinity of the site.

- Water resource impacts – including lowering water levels and reducing yield in water supply wells that may be in the vicinity of the site.

Potential environmental impacts from dewatering are discussed in a separate GWE blog, and you can read an article on dewatering impacts here.

REGULATORY PERMISSIONS FOR DEWATERING

In addition to the requirements of the Planning Authorities, the Environmental Regulator (e.g. in the various parts of the UK - the Environment Agency, Natural Resources Wales, SEPA and the Northern Ireland Environment Agency) may have specific permitting requirements in relation to both pumping and discharge of water from dewatering system. The relevant regulator should be consulted to determine the requirements that apply to a given site.

CONCLUSION

Groundwater can be a significant problem when excavating for basement construction. However, with good planning and the use of suitable methods groundwater need not be a major obstacle. Guidance on good practice for dewatering can be found in CIRIA Report C515 Groundwater Control Design and Practice, which will be updated and re-issued as CIRIA Report C750 in 2016.

GROUNDWATER ENGINEERING LIMITED

Groundwater Engineering is an international company specializing in dewatering, groundwater control and water well engineering for clients in the construction, mining and oil & gas industries. Backed by decades of industry experience and technical expertise we are committed to providing our clients with high quality and cost-effective solutions to their groundwater problems.

We pride ourselves on providing safe, technically sound and environmentally sensitive designs, and delivering them in the field, on time and on budget. Our teams combine geotechnical, hydrogeological, engineering and construction management skills, a strong supply chain, quality equipment and materials and skilled operatives to meet our client’s needs.

Blog

Dewatering for Basement Construction

12 March 2016Groundwater can be a significant problem when excavating for basement construction. This blog discusses the available techniques that can be used to dewater during basement construction.

Read More