Sump Pumping

8 October 2014Groundwater control by pumping (also known as dewatering) is the method of temporarily lowering groundwater levels to allow excavation for construction and mining projects. As discussed in a previous blog, groundwater control can be achieved by pumping methods or, alternatively, by exclusion methods.

The most common types of groundwater control by pumping are – in order of sophistication:

- sump pumping;

- wellpoints;

- deep wells; and

- eductor wells.

There are also some less commonly used dewatering techniques, such as electro-osmosis, horizontal wellpoints and relief wells.

This blog focuses on the use of sump pumping on construction dewatering and mine dewatering projects.

WHAT IS SUMP PUMPING?

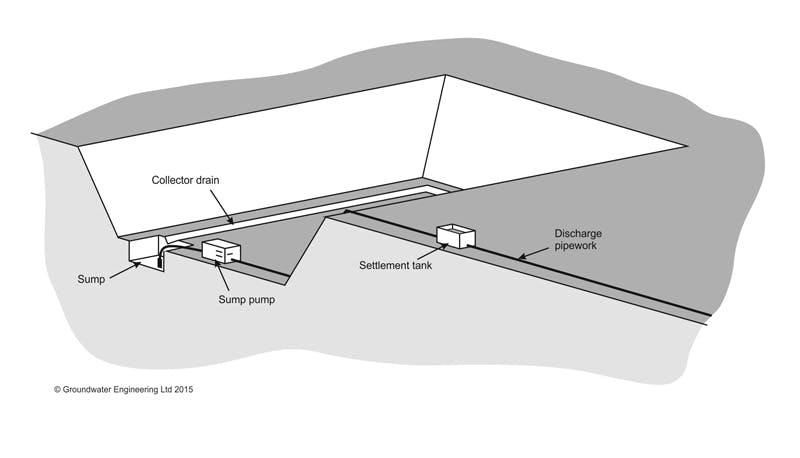

Sump pumping is the simplest form of groundwater control by pumping (i.e. dewatering). In its basic form it involves allowing groundwater to seep into the excavation, and directing the groundwater to localised low points (called sumps) in the excavation. Water collects in these sumps, which are equipped with ‘sump pumps’ – robust pumps with the capacity to handle some solids in the water. Water is then pumped away (perhaps requiring some treatment to remove suspended solids prior to discharge at the ultimate disposal point). Sump pumping is widely used in construction dewatering and mine dewatering (where it is often called in-pit pumping).

Sump pumping can be used for two separate purposes, though the form of a sump pumping system may be similar for either requirement, and a single sump pumping system can meet both requirements in some cases:

- For surface water control: To collect and remove surface water run-off within the excavation, the water being channelled to sumps by means of collector ditches or channels.

- For groundwater control: To collect and remove groundwater seeping into the excavation through the base and slide slopes, the water being channelled to sumps by means of collector ditches or channels.

This blog mainly focuses on sump pumping for groundwater control.

In appropriate ground conditions and for suitable excavation types, sump pumping can be used as the principal method of groundwater control.

Where cut-off walls are used as part of groundwater control by exclusion, sump pumping is often also needed to deal with: residual seepages from any leakages through the wall; the water initially stored in the soil enclosed within the cut-off wall; and any run-off from precipitation falling into the excavation.

REQUIREMENTS FOR SUCCESSFUL SUMP PUMPING

The primary condition for successful sump pumping is that the ground conditions must be suitable for the method. Sump pumping can work effectively in well-graded (i.e. non-uniform, containing a wide range of particle sizes) coarse soils (such as gravelly sands, sandy gravels and coarse gravels) – these are the typical ground conditions in which sump pumping is used for groundwater control on construction projects. Sump pumping can also be effective in competent fissured rock – these are the typical conditions in which sump pumping (or in-pit pumping) is used on open pit mining projects. These ground conditions have the common characteristics that the material (soil or rock) at the level at which the groundwater enters the excavation is not easily destabilized (e.g. loss of strength or movement/erosion of fine particles) by water flowing into the excavation. As discussed later in this blog, problems can occur if sump pumping is used in soils (or very weak rocks) that may be eroded or destabilised by the inflow of groundwater.

Effective sump pumping systems are likely to have some or all of the following characteristics:

Minimal impact on construction and mining operations: The sumps and associated collector drains, French Drains and ditches need to be arranged so far as practicable that they do not interfere with construction operations, haul roads, etc., while still being effective in draining key working areas of the site.

Capability to lower groundwater level as far below current excavation level as possible: The sumps should be dug to a greater depth than the general excavation and should be maintained in their original form throughout the construction period, being deepened as excavation proceeds so they are always the deepest part of the local excavation.

Limited risk of movement of fine particles: The sumps in which the pumps are placed should be designed to have filters (such as granular filter media, perforated pipes, steel mesh or geotextile mesh) to reduce the migration of fine particles toward the sump and to retard any mobile sediment within the water flowing to the sump. For sumps in stiff clay or competent rock this requirement is less critical, but filters are very important for sumps in granular soils.

Reliable operation and adequate back up facilities: The pumps used in sumps should be robust, capable of handling water containing significant suspended solids and be in good condition and well maintained. The need for sufficient pumping capacity is paramount since a greater pumping capacity may be needed to initially dewater an excavation than is required to maintain the groundwater level at a steady state in its finally lowered position. If high rates of pumping from sumps are anticipated then pumping plant could be installed in multiple units so that the additional units required to give the increased capacity for the initial pumping load can be shut down as the required levels are reached. The spare pump sets should be left in position to act as standby in case of breakdown or other emergency.

Low cost and low maintenance needs: Sump pumping is often applied in an ad-hoc fashion as the excavation or open pit is initially deepened, with pumps, discharge hoses, sumps and drain drains deployed in response to conditions encountered. Once the full excavation depth has been achieved (or indeed any significant intermediate stages of excavation are reached) the sump pumping system should be reviewed and, if appropriate, rationalized and simplified. In many cases this may allow considerable cost savings by reducing the number of pumps, lengths of hoses and so on, with a corresponding reduction in plant costs, fuel and power costs.

RISKS AND DRAWBACKS WITH SUMP PUMPING

While sump pumping has great potential for effective groundwater control, it is important to realise that in unfavourable ground conditions the method can lead to major problems.

These problems arise primarily because the flow of water into the excavation, and then to the sumps, can have a destabilizing effect on fine-grained soils. This can lead to fine soil particles (typically silt and sand size) being washed from the soil with the water – this is known as ‘loss of fines’. Loss of fines can lead to ground movements and settlements because material is being removed from the soil, giving the potential for the formation and collapse of sub-surface voids.

Disposal of the pumped water can also create problems, because if loss of fines occurs the discharge water will have a high sediment load, which can cause environmental problems at the disposal point, requiring sediment removal, for example by passing through a sediment lagoon. Where very fine particles are entrained in the water they can be very difficult to settle out, and specialist water treatment techniques may be required.

Soil types where the use of sump pumping has a significant risk of causing loss of fines include:

- Uniform fine sands

- Soft non-cohesive silts and soft clays

- Soft rocks where fissures can erode and enlarge due to high water velocities

- Rocks where fissures are infilled with silt, sand or soft clay, which may be eroded by flowing water

- Sandstone with uncemented layers that may be washed out by flowing water.

In these ground conditions, even the best-planned sump pumping systems are likely to encounter problems. Where sump pumping is assessed to be potentially problematic, it is normally prudent to adopt an alternative method of groundwater control by pumping, such as wellpoints, deep wells or ejector wells with correctly designed and installed filters. Provided the wells are located outside the main excavation area, these methods have the advantage that they draw water away from the excavation, improving stability – avoiding the destabilizing water inflows into the excavation that are associated with sump pumping. The water pumped from wells with adequate filters should be very clear (following an initial period of well development), thereby reducing the requirement to remove sediment from the pumped water.

Blog

Dewatering for Basement Construction

12 March 2016Groundwater can be a significant problem when excavating for basement construction. This blog discusses the available techniques that can be used to dewater during basement construction.

Read More