Relief Wells

5 August 2014There is a wide range of techniques that can be used for groundwater control on construction and mining projects. A previous blog has discussed that groundwater control can be achieved by pumping methods or exclusion methods.

The most common types of groundwater control by pumping are – in order of sophistication – sump pumping, wellpoints, deepwells and eductor wells. However, there is another technique that is sometimes used – relief wells. This blog discusses the potential use of relief wells on construction dewatering and mine dewatering projects.

WHAT ARE RELIEF WELLS?

Relief wells (also known as pressure relief wells or bleed wells) are a type of passive wells used to reduce pore water pressures in confined aquifers or in stratified ground conditions below the base of an excavation. In some circumstances this is necessary to avoid instability of the base of the excavation due to hydraulic uplift or unrelieved groundwater pressures.

A common geotechnical problem that can be mitigated by relief wells is the case when an excavation is made into a low permeability layer (such as clay or unfissured low permeability rock) above a confined aquifer, but where the excavation does not penetrate into the aquifer. In this case there is a risk that the upward pore water pressures in the confined aquifer may cause the base of the excavation to become unstable (these are termed hydraulic failure modes in Eurocode 7). The base of the excavation may ‘heave’ and uplift because the weight and shear strength the of soil or rock remaining between the base of the excavation and the aquifer is insufficient to balance the uplift force from the aquifer pore water pressure.

Relief wells can mitigate this problem by providing an engineered pathway for upward seepage from the confined aquifer into the excavation. This will reduce the pore water pressure beneath the base, improving stability.

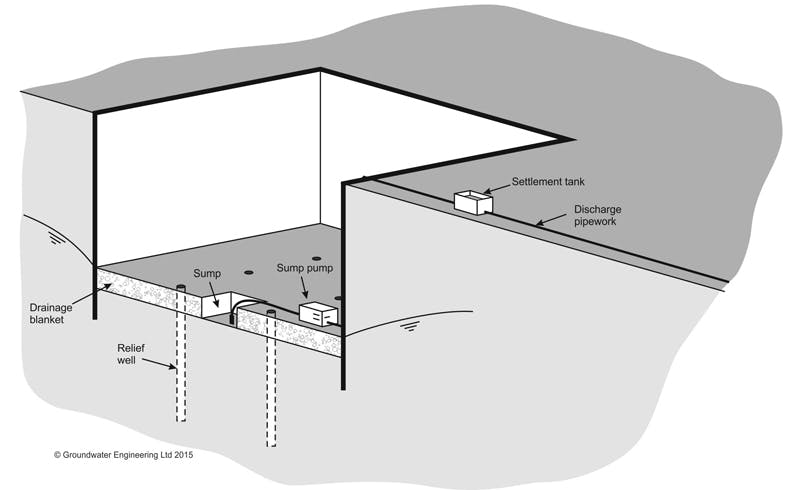

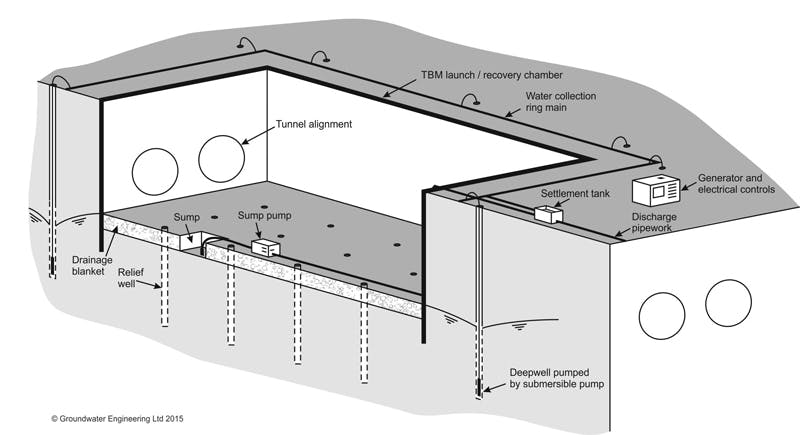

Typically, relief wells are drilled on a grid pattern within the excavation footprint. The wells must be installed before the excavation has extended significantly below the piezometric level in the aquifer. As excavation is deepened below the piezometric level, water will begin to overflow from the wells, relieving pore water pressures in the aquifer and ensuring stability. The water flowing from the relief wells is normally disposed of by sump pumping. A granular drainage blanket and network of drains can be used to direct water to the sumps and prevent ponding in the excavation.

Relief well systems are often termed ‘passive’ or ‘passive well’ systems because the wells are not directly pumped (the wells are effectively pumped indirectly by the sump pumps in the excavation). The relief wells work because they provide preferential pathways for water from the aquifer to ‘bleed’ away, thereby reducing pore water pressures. The flow from the wells is driven by the existing groundwater heads, rather than by artificial pumping.

In groundwater control systems, the term relief wells is typically used to describe wells of relatively large diameter (100 mm to 450 mm) formed by drilling or jetting, and backfilled with sand or gravel, sometimes with a perforated well screen installed. This type of well is distinct from the smaller diameter vertical drains (sometimes known as wick drains or prefabricated vertical drains) installed for soil consolidation purposes, often formed using a mandrel to push plastic drainage wicks into soft clay and silt soils

CHARACTERISTICS OF RELIEF WELLS

When used in appropriate conditions the principal advantages of relief well systems are low cost and simplicity. Relief wells typically consist of a simple gravel-filled borehole; since the wells do not need to accommodate pumps (and are sometimes installed without perforated well screens) they can be of modest diameter, reducing drilling and installation costs. The water flowing from the wells is removed by conventional sump pumps, which are readily available and more robust in use than borehole electric submersible pumps used to pump from deepwells.

Relief wells have the advantage that they can cope with very low well yields. For example, in a low permeability stratum where there is a risk of occasional permeable fissures, average well yields will be low, although wells which intercept permeable features may have higher yields. This may be a problem for borehole submersible pumps in deepwells, which may burn out under low flow rate conditions. In contrast, a relief well system is arranged to let the water from several overflowing wells be collected in an excavation sump, from where it is pumped away by sump pumps. Most sump pumps are capable of running ‘on snore’ at low flow rates and are often better suited to these conditions than borehole pumps.

It is important that the spacing between relief wells is considered in the design process. If small flow rates are predicted then only a few wells may be necessary to deal with the volume of water. However, it may be prudent to install additional relief wells to ensure the distance between wells is not excessive (say no greater than 5–10 m). If the wells are widely spaced and the ground conditions are variable (especially if the wells are installed into fissured rock), there is a danger that the wells may not adequately intercept sufficient permeable zones or fissures. This could lead to unrelieved pressures remaining, with the possibility of local base heave in the areas between the wells.

SUITABLE APPLICATIONS FOR RELIEF WELLS

Relief wells primarily address the stability of the base of an excavation. They are best employed in shafts or deep cofferdams where the sides of the excavation are supported by a structural cut-off wall or other retaining structure and the stability of the excavation base is the primary concern. The method is most appropriate to use where the base of the excavation is in stiff clay or weak rock (such as chalk, soft sandstones or fractured mudstones). Because the water from the relief wells overflows onto the excavation formation, there may be a risk of the water causing softening of exposed soils (especially in clays that have a permeable fabric). This can lead to difficult working conditions. It may be possible to avoid this problem by installing a granular drainage blanket and network of drains to direct water to the sumps and prevent ponding of water in the excavation.

Relief wells are sometimes also used as part of the permanent works on structures and engineering infrastructure, to provide long-term pressure relief for deep structures (e.g. basements or deep railway cuttings) constructed above confined aquifers. Permanent relief wells are often installed with screen and casings to allow the wells to be cleaned out and re-developed if their performance deteriorates after several years of service.

Relief wells are sometimes used in open pit mining to reduce groundwater pressures below the base of the pit. This may be necessary where low permeability layers (aquitards) exist below the pit, and prevent deeper aquifers draining directly into the pit, or where geological structures such as permeable fault zones need draining into the pit in order to reduce pore water pressures as part of mine depressurization programmes. The water from the relief wells is allowed to flow upward where it is collected by the in-pit pumping system.

Blog

Dewatering for Basement Construction

12 March 2016Groundwater can be a significant problem when excavating for basement construction. This blog discusses the available techniques that can be used to dewater during basement construction.

Read More