Good Practice in Pumping Tests

28 April 2014Pumping tests are often carried out in water wells as part of the investigation and design stages of construction dewatering and mine dewatering projects. They are also carried out as part of water resource studies or when assessing the performance of water supply wells as part of well rehabilitation programmes.

Selecting the best pumping test methods, equipment and schedule is vital if the pumping test is to be effective and to provide value for money. Each project and set of hydrogeological conditions are unique and must be assessed individually, but some generic guidance can be given on pumping tests based on experience on other projects and on published guidance.

This blog discusses good practice in carrying out pumping tests in water wells, and highlights some common errors and mistakes.

WHAT IS A PUMPING TEST?

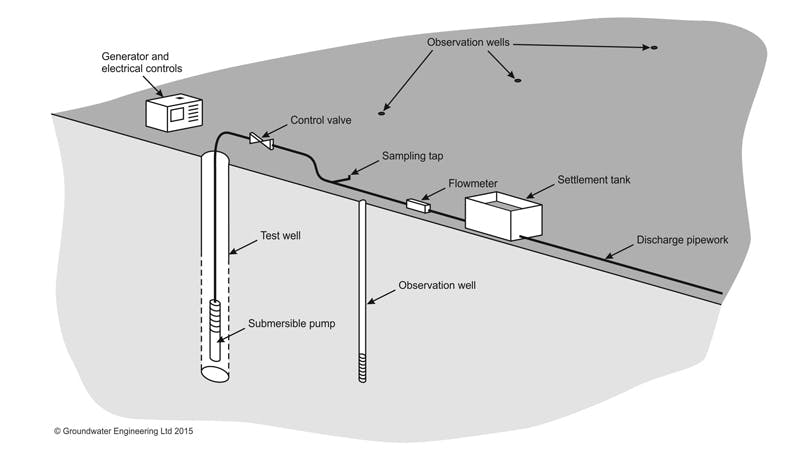

A pumping test is a programme of controlled and carefully monitored pumping to gather data on pumping rates, drawdown of groundwater levels and groundwater quality. The data from pumping tests can be analyzed to provide information on hydrogeological conditions and aquifer parameters such as hydraulic conductivity and transmissivity.

The most common form of pumping test involves pumping from a single well, while monitoring the pumped flow rate and the drawdown in the pumped well and in an array of observation wells, spaced at various distances from pumped well.

During pumping tests the typical duration of continuous pumping is 24 hours to 7 days, although on large scale mine dewatering projects long term pumping tests are occasionally carried out for 30 days or longer. The objective of most pumping tests is to affect the aquifer over a very wide area, and pumping tests may require monitoring of drawdowns several hundred metres from the pumped borehole.

Pumping tests are different to small scale ‘well tests’, such as packer tests or rising and falling head tests. These small scale tests only affect a small volume of aquifer and provide ‘spot value’ hydraulic conductivity results representative of a relatively small volume around the test well. In contrast, pumping tests can provide information on representative aquifer parameters for a much larger volume of aquifer, as is typically needed for dewatering design or water resource studies.

EQUIPMENT REQUIREMENTS FOR PUMPING TESTS

A range of equipment is needed for a typical pumping test.

Pump

Pump choice is controlled by several factors, including: borehole diameter, depth to groundwater level and equipment availability.

Different types of pump can be used in pumping tests. Most commonly, electrically driven borehole submersible pumps are used. If rest groundwater levels are shallow then surface suction pumps can be used. Occasionally, pumping tests are carried out using alternatively pumping methods such as eductors or airlifts.

Power supply

Most pumping tests are set up on a temporary basis, and electrical power is typically supplied from a generator, and not from mains power.

Discharge pipework

A pumping test will generate a flow of water, which must be disposed of. A system of discharge pipework, with associated valves, bends, settling tanks, etc is typically required to convey the pumped water to a suitable discharge point.

Monitoring equipment

Necessary monitoring equipment includes:

• Clocks or other means of time measurement

• Water level measurement devices (dipmeters or water level transducers)

• Flow measurement devices (flowmeters, weir tanks or timed volumetric measurement)

• Water quality sampling and testing equipment.

In most cases electronic datalogging systems are used to record data from water level transducers and flowmeters.

WHEN IS A PUMPING TEST NEEDED?

Pumping tests are carried out as part of wide range of hydrogeological investigations, including:

Water resource studies: with the objectives of determining aquifer parameters, assessing the water resources which can be sustainably abstracted, and predicting the potential yield from water wells in specific aquifer units.

Dewatering system design: with the objectives of determining aquifer parameters and determining the distance-drawdown characteristics for dewatering design purposes.

Geothermal system design: with the objectives of determining aquifer parameters and determining the distance-drawdown characteristics for open loop geothermal system design purposes. If the water is to be re-injected a recharge well test may be included in the test programme.

Remediation system design: with the objectives of determining aquifer parameters and assessing the potential to recover contaminants or to control the migration of contaminant plumes.

Assessing environmental impact: with the objectives of assessing the changes of groundwater level and quality which may result from a long term abstraction (such as for mine dewatering or for a new water supply well).

Assessing borehole performance/deterioration: with the objectives of assessing well performance (such as specific capacity) before and after programmes of well cleaning and rehabilitation.

DIFFERENT TYPES OF PUMPING TESTS

Pumping tests can be applied in several different ways:

Pumping only. This is the most common form of pumping test, where the main part of the test involves continuous pumping from a well (along with the associated pre-pumping monitoring and recovery phase).

Pumping and re-injection. Where water disposal by aquifer re-injection is contemplated it may be appropriate to carry out re-injection tests.

Artesian flow test. Where a well overflows naturally due to artesian pressures it may be possible to carry out a pumping test by controlling the discharge from the well by appropriate valving, and carry out a ‘flow test’ without the need for pumping.

Single or multiple boreholes. While the ‘classic’ pumping test involves pumping from a single well, pumping tests can be carried out by pumping on multiple wells simultaneously.

GOOD PRACTICE IN PUMPING TESTS

Like any form of groundwater investigation, a pumping test should be planned and executed by experienced staff, using reliable equipment, in a safe working environment.

Ideally, the pumping test programme should be divided into several phases:

Pre-test monitoring: Before test pumping begins, the ‘rest’ or ‘background’ water levels should be monitored, ideally for several days.

Equipment test: Once the test equipment is in place, it should be test pumped for a short period (say 15 to 60 minutes) to make sure the equipment is working as expected.

Step test: A step-drawdown test involves pumping the well a small proportion of this maximum yield, and then periodically increasing the pumping rate in a step-wise fashion until the maximum pumping rate is achieved. A step test can be a useful way of assessing the hydraulic performance of the well itself.

Constant rate test: This is the main part of the pumping test, and most commonly involves pumping the well continuously at a constant rate for the test duration.

Recovery monitoring: When pumping is stopped, the recovery of the lowered groundwater levels back toward their original levels is monitored.

COMMON PROBLEMS AND ERRORS IN PUMPING TESTS

There are many common problems which occur when pumping tests are executed without suitable planning and design:

• Inadequate background monitoring. If the pre-test monitoring is not carried out for a long enough time period or with sufficient accuracy, it can be difficult to assess pre-pumping conditions, which will affect the accuracy of the estimated drawdowns from the test.

• Test is of too short duration. If the test is not carried out for long enough, the observed drawdowns may be small in relation to background water level fluctuations, or the cone of drawdown may not expand far enough to reach potential aquifer boundaries.

• Test pumping rate is too low. If the test flow rate is too low, the observed drawdowns may be small in relation to background water level fluctuations, or the cone of drawdown may not expand far enough to reach potential aquifer boundaries.

• Inconsistent monitoring/poor recording. If inaccurate or unreliable monitoring equipment is used, this can mean the field data is potentially invalid. Similarly, if the field team is not adequately trained and briefed in methods and procedures then poor quality test data can result.

• Equipment failure. If inappropriate, poor quality or badly maintained pumping and monitoring equipment are used then the test may be affected, for example if pumping is interrupted due to pump breakdown or generator failure.

• Water disposal problems. It is essential that the pumped water can be disposed of for the entire duration of the pumping phases of the test programme. The water must be piped away to a sufficient distance and suitable location so that it does not recirculate back to the aquifer, and does not cause a risk of flooding or other downstream impacts.

SOURCES OF GUIDANCE ON PUMPING TESTS

There are several national and international standards on well pumping tests which provide useful guidance on carrying out tests and give recommendations on test duration, frequency and accuracy of monitoring. Useful examples are:

BS EN ISO 22282: 2012. Geotechnical Investigation and Testing – Geohydraulic Testing. Part 4: Pumping Tests. British Standards Institution, London.

BS ISO 14686: 2003. Hydrometric Determinations — Pumping Tests for Water Wells — Considerations and Guidelines for Design, Performance and Use. British Standards Institution, London.

KRUSEMAN, G P and DE RIDDER, N A (1990). Analysis and Evaluation of Pumping Test Data. International Institute for Land Reclamation and Improvement, Wageningen, The Netherlands, Publication 47, 2nd edition

Blog

Dewatering for Basement Construction

12 March 2016Groundwater can be a significant problem when excavating for basement construction. This blog discusses the available techniques that can be used to dewater during basement construction.

Read More